The promise of RFID is very alluring for those of us (including yours truly) who strive for maximum efficiency and accuracy. RFID, in many cases, is a heck of a lot faster and easier for collecting a lot of data in an automated way. RFID can detect things you can’t even see, helping to ensure everything is tracked whether a human scans it or not. It’s the way of the future with asset tracking, for sure, but when you dig into the details and start planning a business case for RFID, you realize quickly there are a lot of options with a vast range of price tags.

Today, it is entirely possible to equip a data center with a fully automated RFID solution that can track assets down to a rack location with no human intervention. Possible – but in most cases – extremely cost-inefficient.

The core issue is in hardware costs. RFID technology is expensive, and to fully equip a typical data center requires a lot of it. For example, let’s suppose it costs “X” dollars to install an RFID reader at each entrance and exit. To expand the use of RFID down to tracking at the rack level requires putting readers in every rack, which can easily cost thirty-five times as much as a portal system alone.

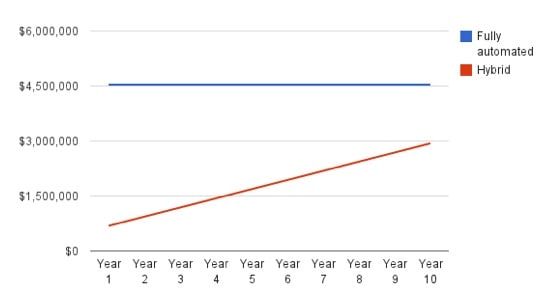

Want real numbers? Cost projections we put together recently for a client (a large bank) revealed the difference in hardware costs alone between an entirely automated RFID system versus a RFID hybrid system using a combination of portal and handheld readers. In the first year, the fully automated system is over $4 million more expensive.

Year-1 Cost – Hardware, Software, Tags and Services

Fully automated: $4,538,088

Hybrid: $ 435,588

Of course, the hybrid system involves labor costs, which accumulate over time. But even with this taken into account (at a projected labor cost of $250,000 per year) the cost savings projected over a ten-year period are dramatic: Over $1.6 million.

10-year Cost (includes hardware, software and labor)

Fully automated: $4,538,088

Hybrid: $2,935,588

Difference: $1,602,500

Our analysis clearly shows the greater cost effectiveness of deploying a hybrid RFID solution using fixed portal readers (which automatically track inventory entering and leaving the facility) with human beings using handheld RFID scanners to track inventory to the rack level.

For questions about how to implement RFID solutions for your company, learn more from AMI or contact us for help.

Author: Tom Watson

Tom Watson is AMI’s President and CEO. He began his career in high tech in 1996, as a software engineer for his own software company. After a subsequent stint at IT Asset Management firm Micropath as senior architect for that company’s asset tracking system, he founded AMI to develop hardware asset tracking technology solutions for enterprise IT Asset Management customers.